A multi-operator sorting process is distinguished by its complexity: several players are required to handle large flows of parcels simultaneously in the same preparation area. This implies strict organisation of tasks, perfect synchronisation of actions, and maximum limitation of human error. In this environment, where every second counts, an error can result in delays and additional costs.

Traditionally, sorting has been based on manual systems based on gestures of forced and repetitive validation. This approach leaves plenty of room for error, particularly in high-speed environments. Faced with this reality, how can the process be made more reliable while improving ergonomics and operational performance? This is where the technological contribution becomes relevant.

Shortcuts :

Explanation and operation of the Beacon device

How do smart LEDs work?

What are the returns on investment? See the results

The challenges of multi-operator sorting in the modern supply chain

In environments where several operators simultaneously manage large volumes of parcels, the complexity of the flows increases significantly, giving rise to a number of challenges. new challenges :

✓ Risk of reversal : filing errors lead to costly disputes and loss of profitability

✓ Lack of synchronisation of tasks between operators: the lack of coordination makes it difficult to meet deadlines and generates errors, creating tensions in the logistics flow

✓ Difficulties in guaranteeing the speed of processes : managing a large volume of parcels puts pressure on operators, threatening the overall rate and increasing the risk of overwork, which impacts the stability of the supply chain

These challenges show just how crucial mastering a multi-operator sorting process is for optimise your supply chain and provide a quality service.

The technological combination: Beacons and smart LEDs

To cover all of the above issues, the two complementary technologies stands out as the solution :

✓ Beacons managed by Epyo software : real-time location coding and automatic validation of the deposit

✓ Smart LEDs : intuitive visual guidance for operators

Combined, these technological contributions redefine the way sorting processes are managedby integrating seamlessly with warehouse management systems (WMS).

Beacons: eliminate manual validations while making deposits more reliable in real time

Beacons are wireless devices strategically placed in the sorting area, at each deposit location. Transmitting a BLE (Bluetooth Low Energy) signal, these beacons communicate in real time with the operator's hands-free terminal (receiver of the BLE signal) for a more precise and accurate identification. perfect synchronisation of physical and IT flows. As a result, Beacons offer an average gain of 6 seconds per package handled by digitising validation actions, while ensuring a high level of quality precise, real-time traceability assets.

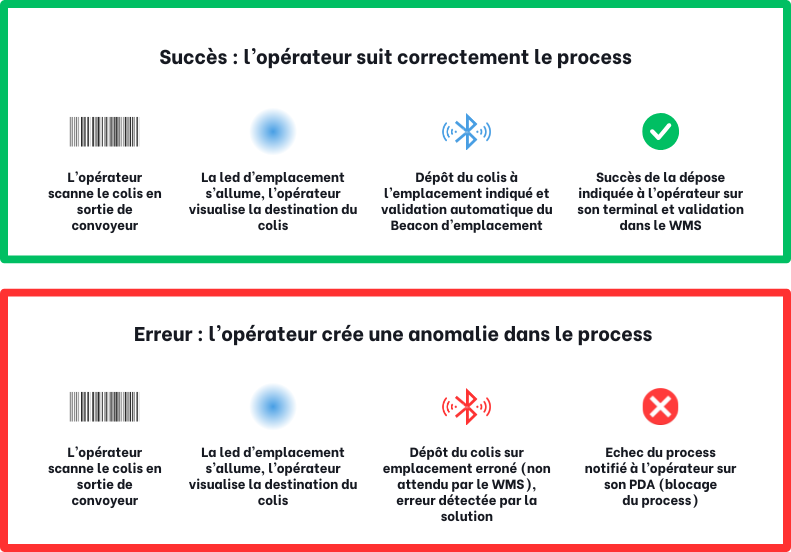

Intelligent LEDs: reducing operator fatigue

To optimise the ergonomics of sorting stations, light guidance works perfectly with Beacons. The intelligent LEDs offer a clear, instant signalling operators on the actions to be taken. For example, when a parcel is scanned at the exit of a conveyor (using a hands-free scanner), the LED associated with the operator lights up to indicate the destination of the parcel, which is then validated "scanless" using the location beacon. This visual system is much quicker to interpret than instructions displayed on a terminal, which drastically reduces processing time and improves efficiency global.

Our partner's Led solution Pickeos is particularly well suited to multi-operator environments, as it ensures that each user receives personalised instructions in real timeThis synchronisation is crucial in modern logistics environments, where speed and precision are the keys to a high-performance supply chain. This synchronisation is crucial in modern logistics environments, where speed and precision are the keys to a high-performance supply chain.

Let's talk ROI: optimised efficiency in multi-operator sorting processes

✓ Eliminating sorting errors Thanks to Beacon technology, the rate of sorting errors has been reduced. reduced to zero. The precision of the connected gestures prevents any reversal of parcels, a major problem in high-speed logistics environments.

✓ Optimising operational performance the time required to process each parcel is reduced by average of 6 seconds. In a production line where thousands of parcels are processed every day, this gain translates into an increase in overall productivity.

✓ Improved ergonomics By freeing up operators' hands and simplifying the operational process, the solution improves ergonomics and reduces physical fatigue. This not only makes it possible to improve the well-being of operatorsof reduce RSIbut also maintain a high level of performance constant for the warehouse

✓ Adaptability and flexibility technology is easily adaptable to different environments and logistics processes. Whether for small sorting centres or large multi-operator platforms, the solution is easy to integrate and improves performance as soon as it is deployed.

Controlling multi-operator sorting is therefore no longer necessarily based on manual processes, but on a system of an advanced technological combination where Beacons and intelligent LEDs redefine the standards for productivity and precision to meet the performance requirements of the modern market. The integration of these solutions enables eliminate errors, improve ergonomics for operators and optimise all sorting operations.

Ready to optimise the efficiency of your sorting process?

→ Contact us